Platform trailer as floor conveyor vehicle

Platform trailer as floor conveyor vehicle

Material handling

We are specialised in all kinds of material handling. Originally from the glass assembly sector, i.e. specialised in a very sensitive material, we are predestined for heavy, unwieldy and demanding materials. Here are a few fields of application for our platform truck where lifting functions would also be possible:

- Tools Punching, casting, forging and casting moulds

- Assemblies Machines, plants and components

- Charging goods Special goods

- Cylinders Drums, coils and rolls

- Pallets Euro, one-way and special goods

- Rectangular container Box, container, KLT and IPC

- Long goods Wood, steel, aluminium, plastic, tubes and profiles

FEM simulation

We use modern techniques for load testing and simulate the occurring loads while still in the design phase in order to develop sustainable machines and components. With the finite element method, we discover weak points well before prototyping and can remedy and simulate them already in the design phase.

Individual solutions for all industries

Industry is the driving force behind the progress of the German economy. To support and simplify - and also secure - work operations, we offer the right lifting equipment for purchase or rent for every industrial application. We have individual solutions for the automotive, mechanical engineering, energy, rail, aviation, defence, shipbuilding, mining, wheels and tyres, chemical, building materials, glass, steel, foundry, textile and paper, rental and removal industries, as well as various special solutions.

Contact us and together with our specialists we will find the right product solution for every sector and industry!

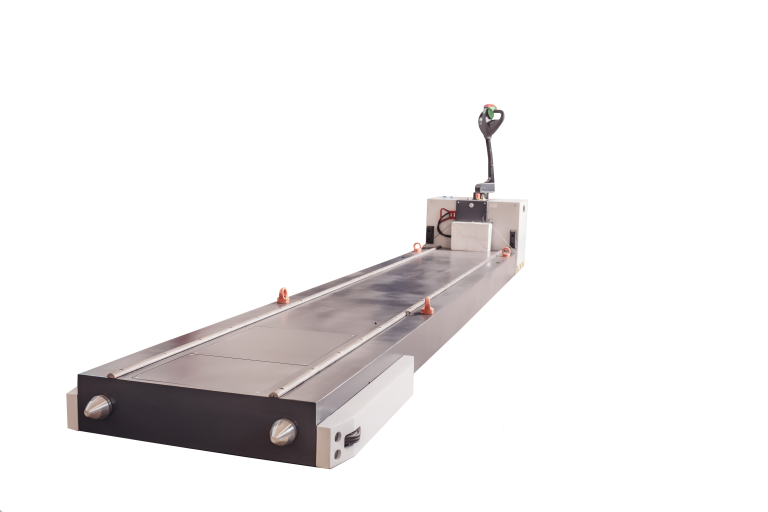

Platform fork lift trailer as pedestrian

Tool change trolley for cylindrical moulds

Our UPK5000 platform truck can transport cylinders weighing up to 5,000 kg. It is designed to be operated as a pedestrian/drawbar unit, and the drive is electric so that it can operate with low emissions in indoor areas. This roller transport trolley was specially developed according to customer requirements and manufactured in our own production facilities. Making work easier and safer is always our focus.

Drive systems

The right drive concept depending on the requirements. We use electric drive concepts that respond to customer wishes and are adapted to the loads to be transported. Safety, durability and ergonomic handling are just a few of the points that go into our design.

Individual programming

We programme our travel and lifting technology ourselves and can therefore respond to customer wishes individually. Sensitivity, speed or the control technology are all part of this. We already have a wide range of options and application scenarios at our disposal.

Material handling for the industry

Spare parts supply

A fast and uncomplicated spare parts supply is an important part of Uplifter's all-round service. We have a nationwide network of service locations to ensure good service coverage.

Efficient tool change: With the Uplifter tool change trolley you save valuable time and energy during the tool change procedure.

Are you looking for a solution that handles your demanding loads with ease? The Uplifter tool change trolley is your ideal partner! As specialists for demanding loads, we know how important a smooth and fast tool change is. Our Uplifter tool change trolley, one of our top industrial trucks, makes this process a breeze. Save time and energy and increase your productivity. Take the next step and experience the difference with our charging trolley. Don't wait, optimise your tool change today with the Uplifter tool transport trolley!

Ergonomic design: Thanks to the well thought-out design of the Uplifter tool changing trolley, you can transport your tools comfortably and without damaging your back.

Experience the revolution in tool transport with the Uplifter tool changing trolley! With its ergonomic design it is easy on your back and increases your productivity. As specialists in industrial trucks, we have developed this charging trolley to transport even delicate coils safely. Benefit from our expertise and discover how easy and efficient the transport of tools can be. Dare to change and go for quality, comfort and durability. Get the Uplifter tool changing trolley now!

High load capacity: The Uplifter tool change trolley is strong enough to transport even heavy tools safely and reliably.

Discover the Uplifter tool changing trolley - your ideal partner for demanding loads. With its high load capacity, no tool is too heavy. Whether on the construction site or in the workshop, this charging trolley transports your tools safely and reliably. Don't let heavy loads slow you down, choose the Uplifter tool changing trolley for effortless transport. Take the opportunity and make your everyday work easier with the Uplifter tool changing trolley.

Space-saving: With its compact size, the Uplifter tool change trolley fits into any work area and allows optimal use of the available space.

Discover the Uplifter tool change trolley, the plant-specific solution for your workshop. This compact trolley not only saves space, but is also a specialist for demanding tasks. It is designed to fit perfectly into any work area, helping to make the most of the available space. In addition to its size, it is the plant-specific charging trolleys that make it an indispensable helper. Make your work easier with the Uplifter tool changing trolley. Try it out now and experience the difference!

Durable and robust: The Uplifter tool changing trolley is made of high-quality materials and is designed for a long service life. So you can enjoy your work companion for a long time.

Increase your productivity with the Uplifter tool change trolley. The ideal helper for industrial trucks at its best. With its robust construction and high-quality materials, it is an indispensable partner in your workshop. Its innovative design enables efficient and safe transport of your tools. Our charging trolley is an all-rounder that significantly improves your workflows and ensures smooth logistics. Don't wait any longer and experience the benefits of the Uplifter tool changing trolley for yourself. Increase your efficiency starting today!

Safety: Thanks to its sturdy construction and non-slip surface, the Uplifter tool changing trolley ensures maximum safety during the transport of your tools.

Discover the Uplifter tool change trolley, your solution for the safe transport of demanding loads. With its robust construction and non-slip surface, it is a specialist in confined spaces. It is one of the most reliable industrial trucks on the market. Rely on the tool change trolley for stress-free transport of your tools. Try the Uplifter tool change trolley for smooth and safe operation.

Flexibility: The Uplifter tool transport trolley is equipped with practical castors so you can move it effortlessly from one place to another.

Our Uplifter tool change trolley is the perfect solution for demanding loads! With its flexibility and robust construction, it is the ideal companion for your specialist industrial trucks. Its innovative design allows for easy and safe transport of your tools. With an Uplifter charging trolley, changing tools becomes child's play. Experience the versatility and efficiency that our Uplifter offers you. Try it out and experience how easy changing tools can be. Don't hesitate to order your Uplifter tool changing trolley now!

Versatile: The Uplifter tool transport trolley is suitable for various work areas such as workshops, production halls or warehouses. So you can use it according to your needs.

Discover the efficiency of the Uplifter tool transport trolley! It is your perfect solution for the safe and convenient transport of tools in different work areas. Whether in the workshop, production hall or warehouse - our charging trolley adapts to your needs. With the Uplifter high lift truck, work becomes child's play. Do you have any questions? We will be happy to advise you! Let us convince you of the quality and versatility of the Uplifter tool change trolley. Try it out now and experience how easy tool transport can be!

Industrial trucks as special construction

- Introduction to in-house processes and their importance.

- Explain the role of drums in in-plant processes.

- Discuss the different types of in-plant drums and their applications.

- Tips on how to optimise the use of drums in your in-house system.

- Conclusions and recommendations for the effective use of drums in in-plant processes.

Please remember to make your writing clear, concise and informative. Use relevant keywords in a natural context and stick to the given word limit. Good luck in writing your document!

- Idea 1: An introduction to the variety of industrial trucks and their applications in in-plant logistics.

- Idea 2: A detailed examination of the safety aspects of handling industrial trucks.

- Idea 3: Practical tips on the efficient use of industrial trucks for the in-house transport of drums.

- Idea 4: A comparison between different types of industrial trucks and their specific applications.

- Idea 5: A detailed guide to the maintenance and care of industrial trucks.

- Idea 6: The role of industrial trucks in optimising in-house logistics processes.

- Idea 7: Case studies on the effective use of industrial trucks in different industries.

- Idea 8: The future of industrial trucks: new technologies and trends.

- Idea 9: The impact of industrial trucks on the working environment and employee efficiency.

- Idea 10: Choosing the right industrial truck for specific in-plant tasks.

What are industrial trucks

Industrial trucks like an ant are special vehicles used in the field of internal transport. They are designed to move goods and materials within a company's premises. Examples of industrial trucks are forklifts, pallet trucks or even electric tractors. These vehicles are essential to optimise the transport of goods and commodities and to increase the efficiency of internal transport. They contribute significantly to increasing productivity and reducing labour costs. Industrial trucks are available in a variety of sizes and designs to meet the specific needs of any business.

Possible applications of industrial trucks

Industrial trucks such as forklifts and high-lift trucks are an integral part of warehouses and production facilities. They are indispensable for efficient material transport. Forklifts are ideal for lifting and moving heavy loads over short distances. At the same time, they are extremely manoeuvrable and versatile. The high lift truck, on the other hand, is ideal for stacking goods at great heights. It is characterised by its stability and high lifting height. Both vehicles contribute to optimising work processes by reducing the physical strain on employees and increasing safety in the workplace. Therefore, they are indispensable in areas such as incoming goods, order picking and outgoing goods.

Types of industrial trucks

Advantages

- Manual industrial trucks like an ant are inexpensive and easy to operate.

- They do not require special licences or training.

- Manual industrial trucks are environmentally friendly as they do not produce exhaust fumes.

- They offer high flexibility as they can be used in many different environments.

- They require very little maintenance compared to powered industrial trucks.

Disadvantages

- Manual unpowered industrial trucks can be physically demanding and are not suitable for lifting heavy loads.

- They can limit productivity as they are slower than powered industrial trucks.

- They have a limited range and cannot be used for long distances.

- They may not be suitable for all types of goods, especially bulky or awkward items.

- They can pose safety risks if used improperly, as the operator has full control of the vehicle.

There are different types of industrial trucks, which vary in their functionality and area of use. Some of the most popular are forklifts, pallet trucks and tuggers. The stacker is ideal for lifting and transporting heavy goods. The pallet truck is mainly used for moving pallets short distances, while the tug is used for pulling large loads. There are also manual and automated versions of these vehicles. Manual industrial trucks or pallet trucks require an operator, while automated vehicles can work autonomously. Each vehicle has its own advantages and disadvantages, depending on the specific requirements of the application.