Special machine construction in our own production

Standard devices of the latest generation and customised special designs!

Special developments from a single source

Use our basic equipment for lifting and transport tasks and let us adapt it to your individual requirements. We are fast in implementation and have a competent development team directly in house, which works out the optimal solution in coordination with your requirements. We offer special construction for the following applications:

- Material handling

- Pedestrian-controlled industrial trucks

- Order pickers

- Transport and logistics

- Transport systems

- Handling and transport technology

- Storage technology

- Conveyor technology

- Lifting technology

- Transport technology

- Industry

Load calculation

We work with FEM simulations in order to be able to identify and eliminate any weak points at an early stage during development.

A strong partner in special machine construction - we develop your future.

Industrylifter

The Industrylifter - the platform solution that revolutionises the lifting and transport market and flexible production! A machine that can be used so flexibly does not exist on the market to date. We are always developing new solutions and turning ideas into reality. Flexible and individual are the buzzwords of the industry of the future.

Individual solutions for all industries

Industry is the driving force behind the progress of the German economy. To support and simplify - and also secure - work operations, we offer the right lifting equipment for purchase or rent for every industrial application. We have individual solutions for the automotive, mechanical engineering, energy, rail, aviation, defence, shipbuilding, mining, wheels and tyres, chemical, building materials, glass, steel, foundry, textile and paper, rental and removal industries, as well as various special solutions. For more than two decades, industry and trade have relied on Uplifter as a specialist for manual handling of glass, wood, metal, plastic and panel elements of all kinds. Vacuum lifters, lifting jacks and automatic systems for parts handling are among Uplifter's core competencies. Whether commercial or industrial production, Uplifter technology saves you valuable time in production: Uplifter stands for efficient handling with the highest ergonomics and without any physical effort.

Modern, automatic handling solutions are designed according to customer requirements, optimised during development and built in Germany according to the highest quality standards. For assembly concepts, we develop individual solutions or advise you directly on site.

In panel and part production, Uplifter's special solutions take over various process steps fully automatically. Examples for the use of automatic handling solutions:

- Area storage

- Buffer storage

- Return systems

- Feeding systems

- ... and many more

Contact us and together with our specialists we will find the right product solution for every sector and industry!

Drum vacuum suction

Lifting and transporting barrels

Requirement: Unloading a truck with empty barrels that are not delivered on pallets. The entire loading area was used for the delivery, which of course makes unloading very difficult. The drum suction cup recognises how many drums need to be suctioned and lifts them easily and safely using vacuum technology.

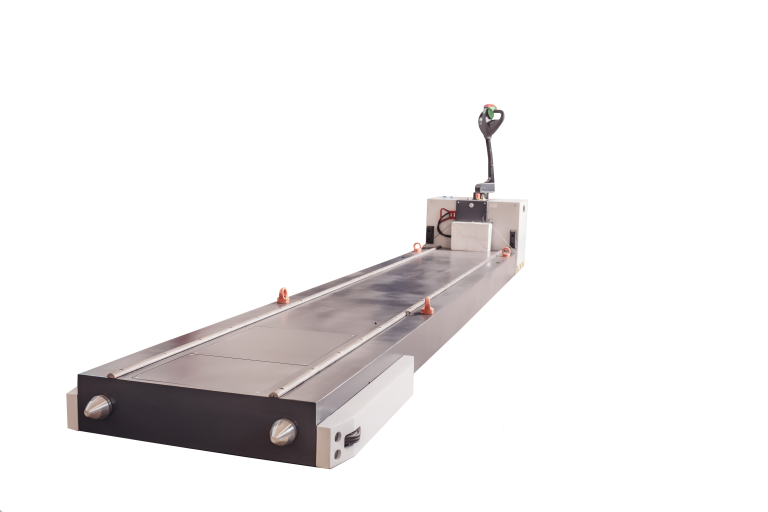

Heavy duty platform trolley/loading trolley

Tool changing trolleys for industry

We have developed a transport trolley specially adapted to individual production for loading machines. This roller transport trolley was specially adapted and manufactured according to customer requirements. The challenge: the weight to be transported and the handling. Fast transport as well as easy handling are always in focus at Uplifter.

References from special construction

Manipulator for material handling

Lifting, turning and transporting doors.

Requirement: Removal of door elements from the warehouse. Transport to the production line and turn at the same time. Put back into storage after production. By means of vacuum technology, smooth surfaces can be sucked up and transported without leaving any residue. An optimal solution, especially for noble and sensitive surfaces.

Automatic palletising robot

Picking of products

Requirement: Automated picking of products in a secured area. A stationary solution with specially specified gripping tools. Stationary solutions such as slewing cranes or small indoor cranes are also possible in special construction.

Drive systems

The right system for every requirement

No matter what your requirements are, when it comes to lifting and transporting goods, commodities or elements, we have over 20 years of experience. We know exactly what needs to be considered and what requirements are placed on the various systems. We are happy to advise you from development to production and service.

PLC programming

Individually adapted machines and devices

PLC programming is part of our overall package. We adapt our software to your needs or develop the right software package individually for you. Specially adapted and tested for the corresponding hardware. Updates or subsequent adjustments are possible at any time.

Warehousing

We also offer warehousing and just-in-time deliveries to best support you.

Supply chains

Our global network of suppliers and customers enables us to respond to customer requirements with the highest degree of flexibility.

Spare parts supply

A fast and uncomplicated spare parts supply is an important part of Uplifter's all-round service. We have a Germany-wide network of service locations to ensure good service coverage.

Caterpillar drive

Platforms with caterpillar drive can also be used as a base. These are characterised by their manoeuvrability, but also by a low point load on the ground. Off-road mobility and inclines are no problem. In addition, you have the choice between abrasion-resistant tyres in black or white for indoor use. A crawler platform can be used for different superstructures: whether it is a crane arm, tool changer or as a platform truck, almost all areas of application are possible.

Slewable crane arm

Mobile mini cranes have become indispensable in industry. Assemblies are becoming heavier and heavier, making material handling more and more complex. Mobile slewing cranes are therefore the ideal solution in cramped machinery. Take advantage of this and make your production particularly flexible. A stationary pillar crane is not very versatile and is costly to install. For a mobile small crane with minimum width and optimised height, even narrow aisles in the production area are no obstacle.

Put your trust in the pioneer and market leader in lifting and vacuum technology! With every machine and system development, you benefit from our expertise from over 20 years of experience in lifting technology. With Uplifter as your partner for contract manufacturing of special machines, you can further expand your competitive advantage. The use of coordinated drive technology and powerful, maintenance-insensitive mechatronics ensures more productivity, efficiency and performance in your company. After-sales service and maintenance of your system are part of Uplifter's comprehensive service offer.

Uplifter is a specialist in drive technology, mechatronics and complete hydraulic systems. We will be happy to provide you with a customised development concept for your special solution or a sustainable optimisation proposal for your existing machines and systems.

Make your enquiry for contract manufacturing now!

Special solution with potential

Uplifter - the specialist for lifting and transport tasks. A frequent requirement in production is to keep the indoor crane free for large tasks and to be able to act flexibly. Here, a mobile indoor crane is the ideal solution. The big advantage: this is remote-controlled and can be moved freely without additional transport equipment. Thanks to the integrated chain platform, this type of mobile crane is very manoeuvrable and can be moved quickly. An electric drive enables emission-free travel and indoor use. No matter what your requirements are, with a mobile and self-propelled indoor crane you are well equipped for all circumstances and open for all future tasks in production.

Special features:

- Load capacity 240 kg

- Lifting height 1.8 m

- operating radius 2.5 m

- Suitable for 2-shift operation (16 h)

- Safety devices during travel

- 360° radius of action

The caterpillar drive of the UPM1225 serves as a basis

Crawler drives are ideal for transporting mobile indoor cranes. They are manoeuvrable and can turn on the spot, which is a great advantage in narrow and winding production lines. In addition, precise positioning is possible without lengthy manoeuvring. A virtually maintenance-free travel drive ensures an ideal and fluid flow in production.

Balancer for fast work

A balancer mounted on the tip of the slewing jib crane ensures fast and uncomplicated working without having to rely on large winches or additional control technology. In production, things have to move fast and here every time saving counts twice.

Special development with your desired components - not a problem for Uplifter, but a duty for us.